Techniques and Tools of The Trade

Chemless Auto Body Technology

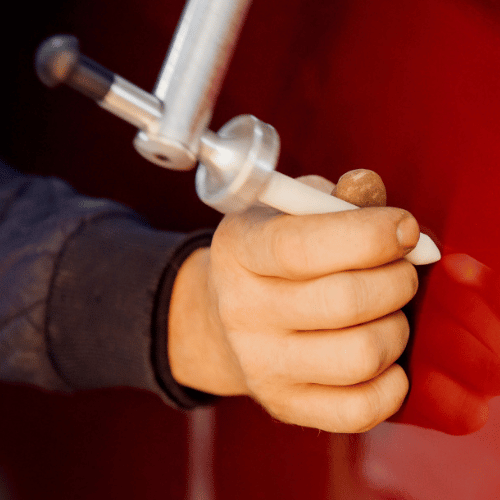

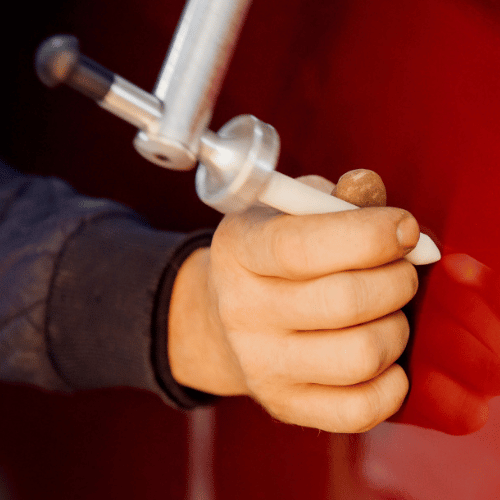

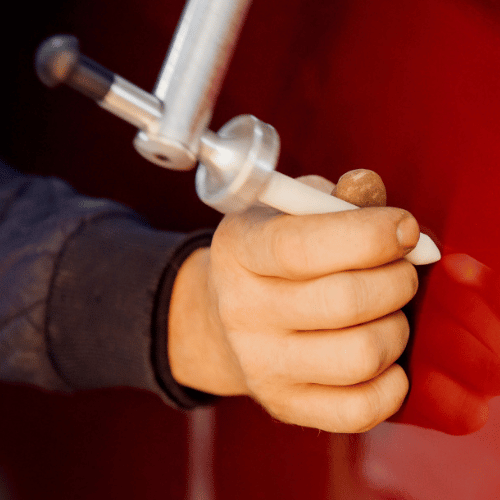

Pull Forming

Pulling metal with specialized equipment from the outside.

Dry Forging

Sculpting metal back to its original shape from the bottom.

Punch Forming

Reshaping panel from the front or back side of the panel – point by point

Induction Form

advanced tools for manipulating the metal with static heat

Annealing

Specialized heating of the panel to make the metal and paint more malleable

Wet sanding

Fine sanding the paint finish is used to remove minor signs of repair

Polishing

Specialized finish compounds used to bring back factory shine

Punch Blending

Methodical tapping and precision hammering for sculpting metal

Electro Forging

High frequency stabilization of stretched metal cells to temper the metal strength

Pneumatic Forging

Pneumatic hammers to re-sculpting badly damaged panels

Gaining Access

Properly gaining access to the back of each dent With R&I

HD Lighting

Lighting and perspective is used to insure a proper repair

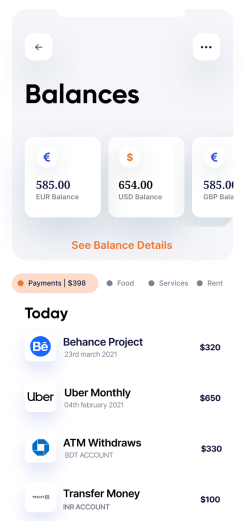

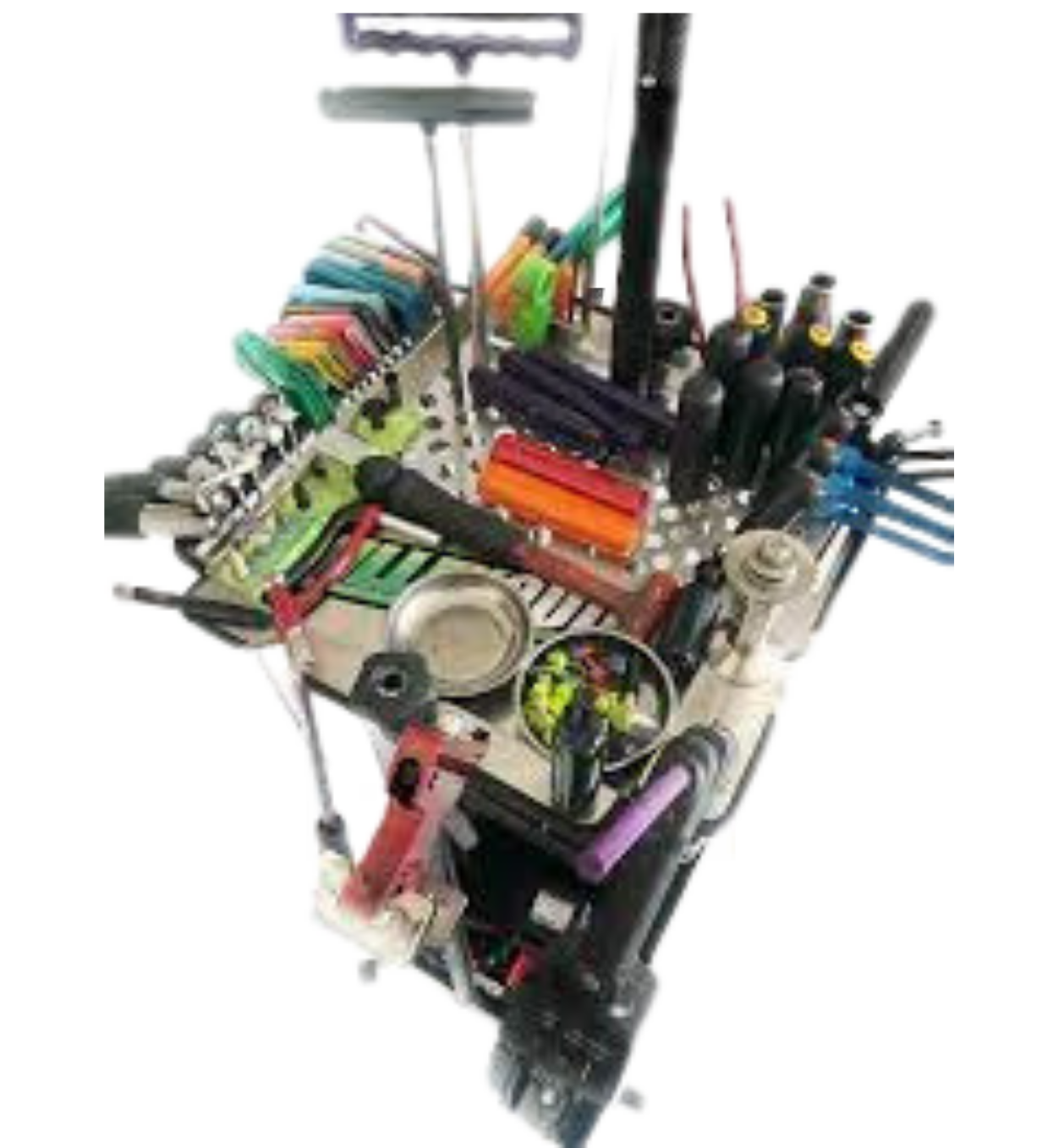

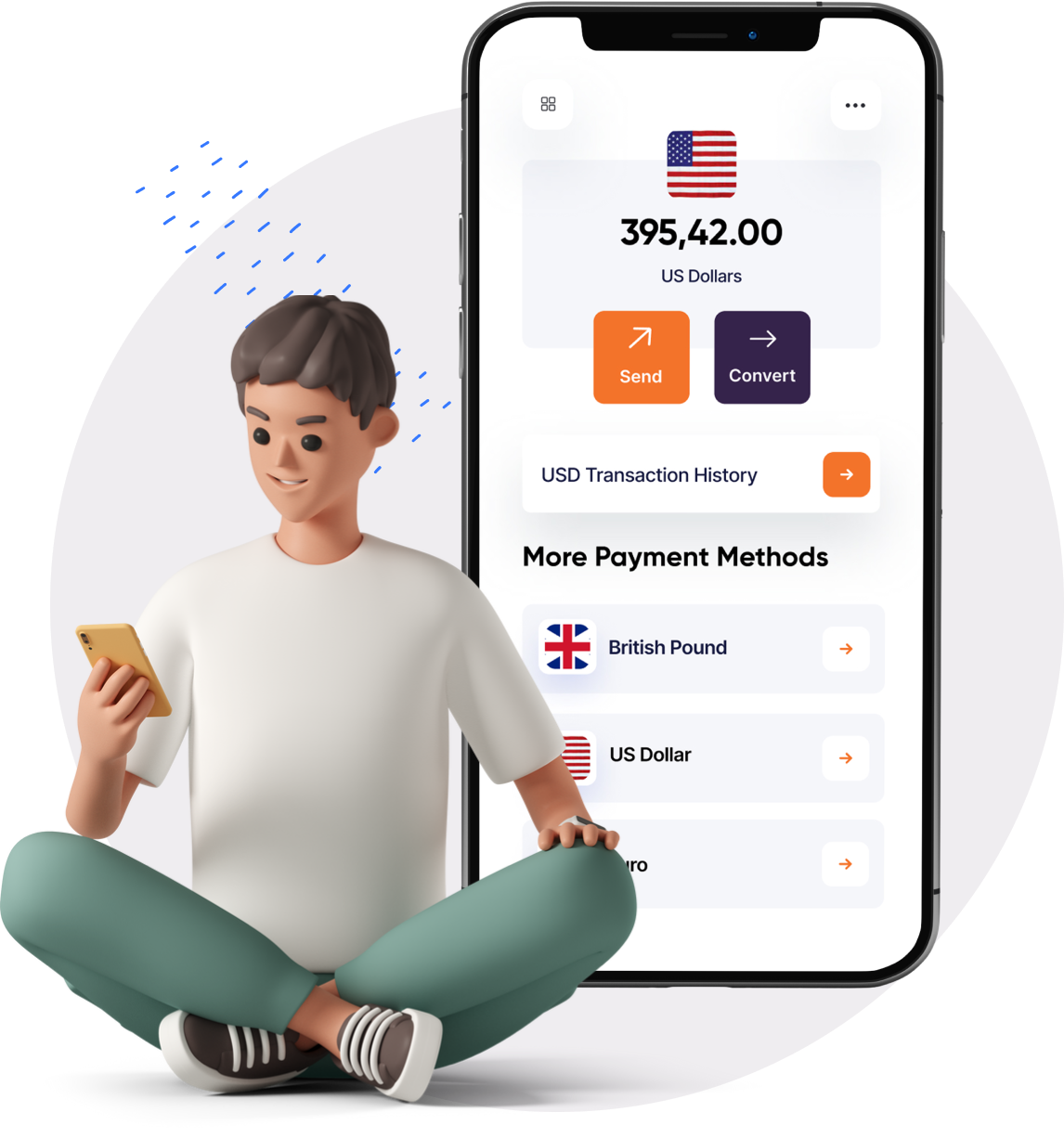

<–Example Of Tool Cart Used

What makes Chemless better than conventional repairs?

It is not that one is better than the other as they are essentially different sides of the same coin. Auto body services have been around since the advent of the vehicle and Chemless Auto Body is simply the advanced techniques that have evolved from the conventional methods.

Faster Repairs

Typically faster than regular methods in most instances and vehicle damage types.

Best Results

Achieves the best possible repairs saving your vehicles factory paint and finish.

Less Wasteful

Much less wasteful than contemporary methods because we can save parts and avoid painting as much when possible.

Skilled Master Artisans

The AutoBody Technicians Of Tomorrow Are Artists

Unlike conventional body shop techniques where you just drill, weld, yank and bondo the problem away – Chemless Auto Body requires much patience, and expertise to achieve the best possible results.

Sometimes a combination of older methods and newer methods are required to achieve the best result but it’s always best to start with Chemless as it will minimize risk, waste and unecisary expense.

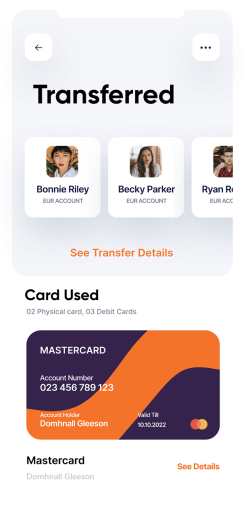

Price Comparison

Repair Pricing

Conventional Auto Body

$55-$74 /per hour

Requires Paint

Parts Replacement

Might Be Required

Chemless Auto Body

$74-$148 /per hour

May Not Require Paint

Keep Original Paint

Keeps Original Panels

Online Marketing

Painting & Finishing

$54-$74 + $36-$45 /per hour

Looses Factory Finish

Takes Much Longer

Dust & Particles Get Everywhere

Testimonial

What Clients Say About This Technology

This type of repair saved my classic car from having to be butchered, bondoed, and painted. I got to keep my original parts, paint and finish. Best of all they did it for less than the restoration shop wanted to charge me and the results were superb. I’m certain it was much better than the custom shop I was going to hire to do the work.

David Brown

Classic Car Owner

Watch Video

Chemless Auto Body Is The Best Possible Repair

From car gurus, insurance companies, to manufacturers all agree that Chemeless Auto Body is the closes way to get your vehicle back to factory conditions which is why they all endorse this type of repair more than any other type of repair.

Behind Process

Repair System

Before & After

Hail Damage Repair With No Paint

Case Studies

In depth research studies about the process and quality of Chemless Auto Body

Auto Hail Restorations

There is no better method to repair auto hail damage on your vehicle.

Paintless Auto Body

Master artists in the art of paintless dent repair have been doing a branch of this repair for over 30 years.

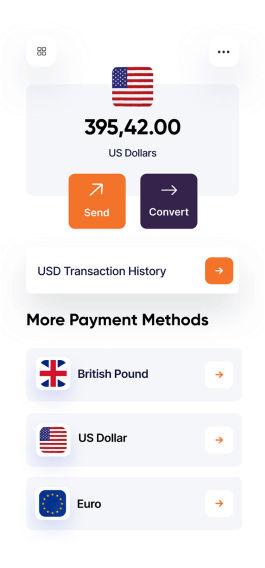

How It Works

Manage It All In This All New System

Get In The Know!